PRODUCTS

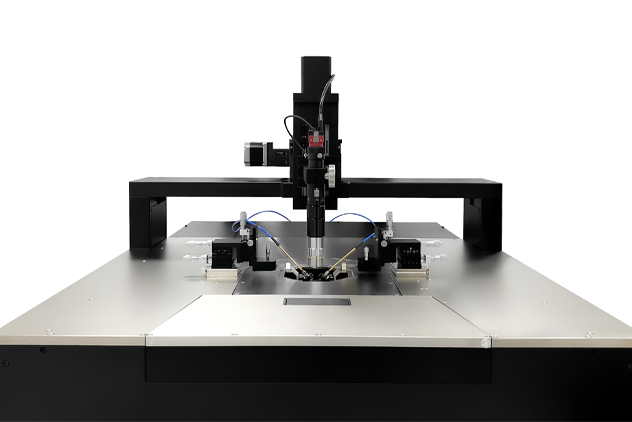

F1 Probe Station

· The probe station can be configured by selecting F1+futureC+instrument.

· Please call Eoulu service hotline 4008808776 for professional engineer support!

Category:

Probe Station

Contact Information

CONTACT NOW- Product Features

- Product Mix

- Product Parameters

- Instructions

-

The world's first evolvable and able-to-learn probe station

Eoulu owns 100% of intellectual property rights

Eoulu's patented design for new digital 3.0 system

makes the probe station simpler and lighter

The world’s smallest 12-inch probe station, only 1 meter wide

Save the cost of clean room and make it easy to move

A dynamic map and static map system with Eoulu's copyright and patent

makes the probe station faster and more accurate

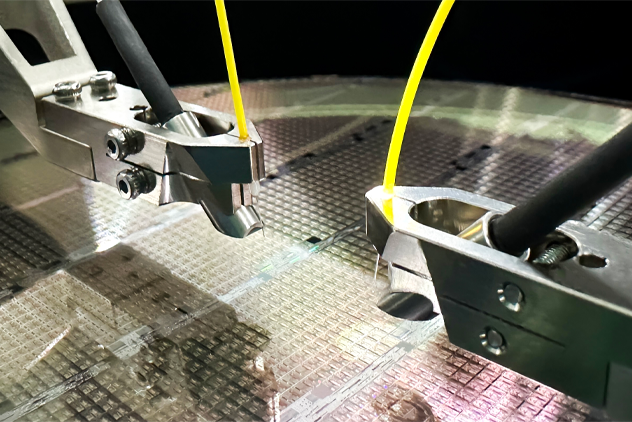

Eoulu’s patented “Near-Zero Error (C0)” and “Virtual Ruler (VR)” technologies

specially used for uneven wafers

The F1 architecture completely solves the problem of inaccurate probing

It is a model that all peers will surely follow.

-

-

F1 Mechanical Performance

No. Item Chuck X-axis Y-axis Z-axis Theta axis 1 Travel 301 mm 301 mm ≥ 10 mm 10° 2 Maximum positioning accuracy * ≤ 0.05 μm ≤ 0.05 μm ≤ 1 μm ± 0.003° 3 Speed ** ≥ 50 mm/s ≥ 50 mm/s ≥ 20 mm/s / 4 Maximum speed 150 mm/s 150 mm/s 35 mm/s / 5 Wafer uneveness adaptability * 100 μm 6 Average time of mapping *** Minimum value Typical value Maximum value < 500 ms < 1 s < 3 s**** 7 XY position locking ***** Minimum value Typical value Maximum value 0.02 μm 0.038 μm 1.5 μm 8 Z position locking Minimum value Typical value Maximum value 0.65 μm 3.5 μm 15 μm * When C0 and VR are enabled

** The speed at which F1 chuck moves varies depending on the chuck size chosen by the customer, the chuck construction (Coax or Triax), and whether the chuck supports high and low temperatures

*** This time only refers to the mechanical movement time and does not include alignment time. There will be some variation depending on the size of the DUT, movement precision, and stability requirements

*** High speed and high stability cannot be achieved simultaneously. Eoulu can provide services to optimize test accuracy or test speed according to the customer'swafer and measurement application. For more information, please contact sales for hardware and software upgrade solutions

**** In the case of 8-inch, room temperature, and triax chuck, F1 adopts the highest accuracy and most stable speed mode, 1000 μm * 1000 μm chip movement time

***** It varies according to the configuration and the customer's requirements for accuracy and speed. The minimum value of XY position locking can be achieved by selecting CCD, which cannot be achieved by standard CCD.

****** The standard deviation of the probe scrub mark length σ is ≤ 5μm. We can refer to the futureD product data of Eoulu to measure more than 2,000 DUTs of 8-inch wafers. Under the high-precision wafer running mode, the probe scrub mark length difference from DUT to DUT is guaranteed to be within 3σ

****** The standard deviation of the starting position of the probe mark σ is ≤ 8μm. We can refer to the futureD product data of Eoulu to measure 2000 DUTs of 8-inch wafer. Under the high-precision and low-speed wafer running mode, the difference in starting position from DUT to DUT is guaranteed to be within 3σ

****** The above data indicators are not lower than the level of peers,refer to the article published by the peer on August 22, 2022

F1 Shielding Capability

No. Shielding and Noise Capability * 1 Light attenuation ≥ 150 dB ** 2 EMI shielding ≥ 20 dB 0.5-20 GHz (typical) 3 Spectral noise floor ≤ -150 dBVrms/rtHz (≤ 1 MHz) 4 System AC noise ≤ 15 mVp-p (≤ 1 GHz) 5 * Eoulu F1 low noise test system supports 1/f,RTS,RTN test. When purchasing low noise test probe station, plesase purchase grounding service and

commissioning service

* In addition to the system capability, environmental conditions should also be considered. This project is not verified on the customer side, and can

be arranged to be verified in Suzhou laboratory of Eoulu

** The single-photon test requires additional shielding devices,this parameter is not applicable

** The test light path refers to the perpendicular incident light from 90° directly above the microscope

** The light shielding wavelength is 200 ~ 2000 nm

F1 Vibration Isolation Capability

No. Vibration Isolation Capability *

1 Natural frequency (vertical) 2.5 ~ 2.7 Hz 2 Natural frequency (horizontale) 2.0 ~ 4.5 Hz 3 Vertical damping (adjustable) 6% ~ 20% 4 Horizontal damping 5% ~ 6% 5 Air pressure 0.3 ~ 0.5 Mpa 6 Maximum load 1600 kg 7 Isolation efficiency 5% ~ 6% 8 Response time to external excitation < 1 s 9 Vibration isolation level VC-C * For the F1 vibration isolation table related parameters, please refer to the manufacturer traceability index. This project is not verified on the customer side

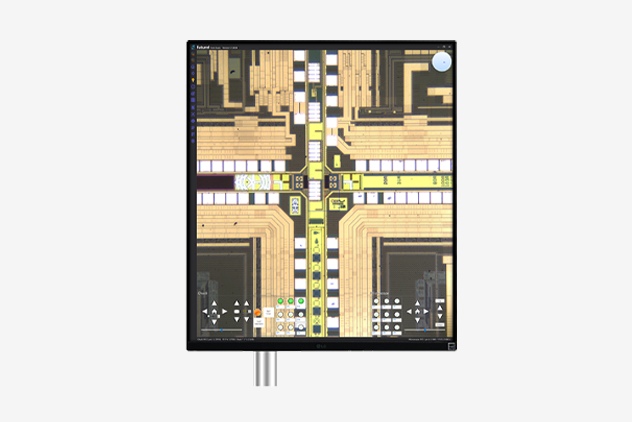

F1 Microscope

Microscope Bridge No Item X-axis Y-axis Z-axis 1 Travel 50 mm 50 mm 90 mm 2 Maximum positioning accuracy ± 2 μm ± 2 μm ± 2 μm 3 Speed 60 mm/s 60 mm/s 120 mm/s Microscope * No Item Large FOV High Resolution 4 Typical magnification ** 225 X 500 ~ 2000X or higher 5 Typical optical lens resolution *** 3.0 μm ≤ 1.5 μm 6 Product picture

7 futureI image

* The F1 probe station is available in both Large FOV and High Resolution microscope configurations, you can choose according to your test requirements

** When the CCD configuration is different, the color and magnification will be different

** When the objective lens is different (5X, 10X, 20X, 50X, 100X), the magnification will be different

*** When the lens configuration is different, the resolution will be different

F1 Chuck

No. Item Chuck size 8-inch 12-inch 1 Temperature range Room temperature High and low temperature Room temperature High and low temperature 2 Maximum operating

temperature range *

- -60 ~ 300°C - -60 ~ 300°C 3 Typical temperature range ** - -60 ~ 150°C

-60 ~ 200°C

-60 ~ 300°C

-40 ~ 150°C

-40 ~ 200°C

-40 ~ 300°C

0 ~ 100°C

0 ~ 200°C

Room temperature

~ 150°C

Room temperature

~ 200°C

Room temperature

~ 300°C

- -60 ~ 150°C

-60 ~ 200°C

-60 ~ 300°C

-40 ~ 150°C

-40 ~ 200°C

-40 ~ 300°C

0 ~ 100°C

0 ~ 200°C

Room temperature

~ 150°C

Room temperature

~ 200°C

Room temperature

~ 300°C

4 Temperature accuracy ± 1°C ± 1°C 5 Temperature resolution 0.1°C 0.1°C 6 Triax chuck leakage (non-thermal) Standard : ≤ 132 fA

Low-Leakage : ≤ 65 fA

Standard : ≤ 231 fA

Low-Leakage : ≤ 65 fA

7 Triax chuck noise (non-thermal) Standard : ≤ 30 fA

Low-Leakage : ≤ 16 fA

Standard : ≤ 42 fA

Low-Leakage : ≤ 16 fA

8 Cooling mode Liquid cool and air cool are optional 9 Typical transition time***

(Liquid cool)

- 60°C → 25°C:23 min

25°C → 300°C:28 min

300°C → 25°C:25 min

25°C → - 60°C:37 min

- 60°C → 25°C:23 min

25°C → 300°C:28 min

300°C → 25°C:25 min

25°C → - 60°C:37 min

10 Typical transition time***

(Air cool)

- 60°C → 25°C:9 min

25°C → 300°C:25 min

300°C → 25°C:12 min

25°C → -60°C:29 min

- 60°C → 25°C:9 min

25°C → 300°C:25 min

300°C → 25°C:12 min

25°C → -60°C:29 min

11 Maximum heating power 5.5 kW 12 Maximum cooling power 12.5 kW 13 Maximum refrigerant flow 5 m / s 14 Maximum transport pressure 4 bar 15 Maximum voltage (high power option) *** 10000 V 16 Maximum current (high power option) *** 800 A 17 Statement It shall be operated and stored strictly in accordance with the temperatureand humidity

specified in "Environmental conditions" in this Manual.

Before the probe station leaves the factory, wafers shall be placed on chuck for performance

verification and reliability test. Therefore, the scratches on the surface of chuck or the movable

plate cannot be completely avoided.The scratches do not affect the use of the probe station

and are not considered as a quality problem.

Before the thermal probe station leaves the factory, heating and cooling test shall be conducted

on the thermal system and thermal chuck.Therefore, the baking marks on the surface of

the chuck (e.g. chuck color change and water vapor mark)cannot be completely avoided.

The baking marks do not affect the use of the equipment and are not considered as a quality

problem.

When ambient temperature fluctuations occur, thermal expansion and contraction of

equipment hardware constitutes a normal operational phenomenon.

To ensure the reliability and consistency of test results, if the probe station remains continuously

powered on and idle for 24 hours or longer, the user must perform system recalibration and

reinitialize parameter settings.

For high-precision, extended-duration (>6h) metrology of individual wafer,

implementation of the Eoulu software application kit with associated service package is

recommended.

If ESD (Electrostatic Discharge) protection is required for the equipment, please explicitly

state this before procurement. The F1 Probe Station provides ESD protection for key modules

(Chuck, Robotic arm ). However, please note that ESD protection cannot be guaranteed for all

components of the equipment. Certain materials and structures cannot achieve ESD protection

through conventional processes. Forced modifications may lead to performance degradation,

reduced service life, or significantly increased costs. Any equipment malfunctions resulting from

such modifications will not be covered under the product warranty.

18

Safety statement This product is driven by 24 V DC motor, with an operating voltage level comparable to that of a personal computer (PC). It complies with the specifications for SELV (Safety Extra-Low Voltage) circuits as defined in IEC 61010-1 and meets the protection class against electric shock for Class III equipment as specified in IEC 61140. Based on this design, the Emergency Stop Device (EMO) or Electromagnetic Braking System (EMS) does not provide additional safety benefits.

Note: This statement does not affect other mechanical safety requirements that the equipment

shall meet.

19 Cleaning Clean the probe station once a month. Use a soft dust-free cloth to remove the dirt from chuck.

If lots of dust and debris are generated during use,cleaning frequency shall be increased.

Do not use isopropyl alcohol(IPA) or any other chemicals on the chuck, as improper use

of solvents or grinding agents may damage the probe station.

20 Maintenance No items can be placed on the chuck except the device under test.

If the screws are loose, promptly tighten them carefully and evenly according to the torque

requirements. If necessary, contact the Eoulu's service team for treatment.

For the fully-automated probe station, ensure that the power supply has been properly

shut down during maintenance or when not in use, and ensure they do not accidentally

restart before maintenance is completed or before use.

21 Service For probe station with a high utilization rate, it is recommended to conduct operational

inspection and service of the chuck once a year.

The following services can only be executed by Eoulu's team:

1. Leveling and calibration of the chuck X/Y/Z/Theta stage

2. Disassembly and installation of the chuck

22 Eoulu high performance thermal Chuck

* Users can choose in these temperature ranges according to test requirements

** For other temperature ranges, please contact Eoulu's sales

** The larger the temperature range, the higher the purchase cost. Testing below room temperature requires cooling, and the lower the temperature,

the higher the purchase cost. Please select the appropriate temperature range according to the actual test requirements

** Automatic wafer testing in high and low temperature,it is recommended to use motorized positioners

*** Measured in 20°C~24°C , 40%~50% humidity

*** High voltage and high current cannot be reached at the same time

*** Higher voltage or higher current need to be customized

F1 Control Software future interface (futureI)

No. Item futureI function 1 Single-page operation Included 2 Autofocus Included 3 2 Points Align Included 4 Auto Align Included 5 AutoZ Included 6 High speed AutoZ Optional 7 Twin-rudder operation * Microscope and chuck movement 8 futureI interface * 9 futureI and Eoulu integration

software futureC seamless

connection makes test easier *

10 futureI and Eoulu data software

futureD seamless connection makes

data processing easier *

* Eoulu copyright

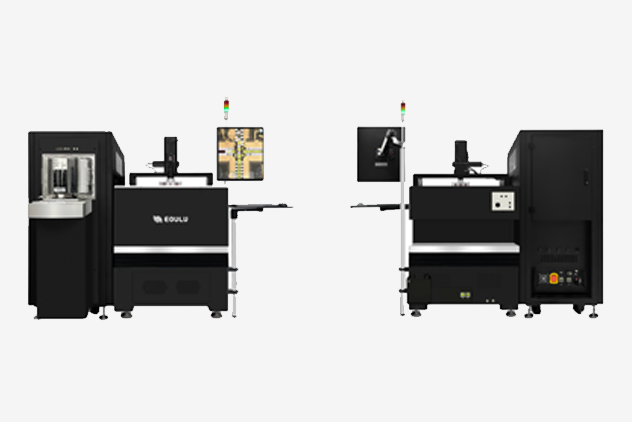

F1 Dimensions and Weight

No. Item Semi-automated Fully-automated 1 Typical dimensions

(W x D x H)

~1500 x 1115 x 1543.5 mm *~2063 x 1620 x 1954 mm **2

Maximum dimensions

(W x D x H)

~1750 x 1465 x 1613.5 mm~2373 x 1620 x 2004 mm3 Main dimensions

4 External view 5 Weight Probe station Thermal system

(Liquid Cooling)

Thermal system

(Liquid Cooling)

Loader ~ 850 kg~ 180 kg~ 180 kg~ 345 kg * These dimensions include the adjustable stands for LCD, mouse and keyboard. The dimensions are only typical values.

** These dimensions include the adjustable stands for LCD, mouse and keyboard, and the tricolor light. The dimensions are only typical values.

F1 Facility Planning

1 Environmental conditions Operating Ambient temperature: 17°C ~ 25°C, ± 0.2°C

Relative humidity: 20% ~ 60%

Storage Ambient temperature: 10°C ~ 30°C

Relative humidity: ≤ 50%

Storage time: ≤ 6 months

(When the storage time exceeds 6 months,it needs to be powered on for 24 hours)

Ambient vibration (including floor) On the horizontal floor, equivalent uniform live load ≥ 200 kg/㎡

Maximum level 100 micrometers/sec,rms (ISO Operating Theatre level) *

Laboratory cleanliness: General laboratory

(The requirements for the F1 operating and storage environment

described in this Manual must be met)

Recommended to be placed in Class-10,000 clean room and above **

2 Power Semi-automated probe station Probe station: single-phase 220 VAC ( +7%, -10%) ***,

50/60 Hz, 1800 VA, GB 10A socket

LCD, computer host, and vacuum pump: single-phase 220 VAC (+7%, -10%) ***,

50/60 Hz, 1000 VA, GB 10A socket (3-way, power strip)

Fully-automated probe station Probe station: single-phase 220 VAC (+7%, -10%) ***, 50/60 Hz, 1800 VA, GB 10A socket

LCD, computer host, and vacuum pump: single-phase 220 VAC (+7%, -10%) ***,

50/60 Hz, 1000 VA, GB 10A socket (3-way, power strip)

Loader: single-phase 220 VAC (+7%, -10%) ***, 50/60 Hz, 1000 VA, GB 10A socket

Thermal system Controller: single-phase 220 VAC (+7%, -10%) ***, 50/60 Hz, GB 10A socket

Chiller (Liquid cool): three-phase 380 VAC (+7%, -7%) ***, 50/60 Hz, GB 32A 5-core aviation socket

Chiller (Air cool): three-phase 380 VAC (+7%, -7%) ***, 50/60 Hz, GB 32A 5-core aviation socket

3 Clean Dry

Air ******

(CDA)

Room-temperature probe station Air pressure: 4.5 ~ 8 bar (65 ~ 116 psi)

Dew point: ≤ -20°C

Connector *****:

Semi-automated: 8 mm OD (CDA 1)

Fully-automated: 8 mm OD (CDA 1) and 8 mm OD (CDA 2)

High and low-temperature probe station Testing at low and high temperatures, the following conditions must be met to keep Chuck frost-free:

Air pressure: 4.5 ~ 8 bar (65 ~ 116 psi)

Continuous flow:

Liquid cool: ≥ 100 l/min @ 4.5 bar

Air cool: ≥ 400 l/min @ 4.5 bar

Dew point: ≤ -70°C (when the lowest test temperature is -60°C)

Oil less than 0.01 mg/m³ ****

Connector *****:

Semi-automated: 8 mm OD (CDA 1)

Fully-automated: 8 mm OD (CDA 1) and 8 mm OD (CDA 2)

4 Vacuum ****** Air pressure (absolute vacuum) ≤ 0.4 bar @ 10 l/min Air pressure (relative vacuum) ≤ - 0.6 bar @ 10 l/min Continuous flow ≥ 10 l/min Connector ***** Semi-automated: 8 mm OD (VAC 1)

Fully-automated: 8 mm OD (VAC 1) and 8 mm OD (VAC 2)

5 Accessories Air compressor Temperature range (liquid cool) Part Number Room temperature I-001 -60 ~ 150°C I-002 -60 ~ 200°C -60 ~ 300°C -40 ~ 150°C -40 ~ 200°C -40 ~ 300°C 0 ~ 100°C 0 ~ 200°C Room temperature ~ 150°C Room temperature ~ 200°C Room temperature ~ 300°C Vacuum pump - K-001 6

CDA and VAC Connectors * Refer to Generic vibration criteria for vibration-sensitive equipment

** Refer to the international standard ISO 14644-1

*** According to the requirements of the national standard GB/T 156-2007

**** According to the requirements of the international standard ISO8573-1

***** Refer to the international standard ISO 14743:2020

***** For the positions of interfaces CDA 1, CDA 2, VAC 1 and VAC 2, see the following CDA and VAC Connectors diagram

****** Measured in laboratory at Standard Ambient Temperature And Pressure (SATP). For more information on CDA pressure and flow,

please consult Eoulu

F1 Service Center *

Service category Service content Part Number Hardware service

(Installation)

• System installation (mass production mode) SRV-301 • System installation (analysis mode) SRV-501 • Accessory installation SRV-305 • System reinstallation SRV-306 • Instrument connection SRV-307 • Ground connection SRV-308 Hardware service

(Calibration)

• Accuracy calibration SRV-503 • Temperature calibration SRV-505 • Loader calibration SRV-506 Hardware service

(Training)

• Probe station operation

(mass production mode)

SRV-303 • Probe station operation (analysis mode) SRV-502 • RF calibration SRV-202 • Instrument operation SRV-203 Hardware service

(Others)

• Probe station PM PM-F1 • Probe station relocation RELO-F1 • Accompanying service SRV-201 Software service

(Installation)

• On-site installation SRV-101 • Remote installation SRV-103 Software service

(Update)

• Platform function SRV-607 • Platform version SRV-606 • Test script SRV-608 • Instrument driver SRV-609 • Plug-in update SRV-701 Software service

(Training)

• Software operation SRV-605 • Driver development SRV-603 • Script development SRV-702 Software service

(Others)

• Operation consultation SRV-706 • Troubleshooting SRV-703 • Accompanying service SRV-705 Application service • IV test SRV-707 • CV test SRV-708 • RF test SRV-709 • SiPh test SRV-801 • Blue tape test SRV-802 • Fixture test SRV-803 • MMIC test SRV-805 • Automatic test SRV-806 Delivery service • Urgent service SRV-807 • Insurance SRV-808 • Unloading SRV-809 • Exclusive vehicle SRV-901 • Storing SRV-902 • Upstairs delivery SRV-903 • Cleanup SRV-905 * For details of service quotation, please contact Eoulu's sales.

Product parameters are subject to change without prior notice.All product images are subject to the actual products, and Suzhou Eoulu System Integration Co., Ltd. reserves the interpretation right for the content.

Related Products

Please leave your contact information and our professionals will contact you as soon as possible!